As 2025 approaches, Indian food companies find themselves at a make-or-break moment where following food regulations also opens new doors. The Food Safety Modernization Act, or FSMA, has turned the worldwide food safety game upside down by moving us from patching things up to stopping problems before they start. If you plan to export food to the U.S., FSMA has become the must-have pass for the global market, not a nice-to-have sticker.

This change is not just about checking boxes; it's an invitation to become a market leader. By adopting preventive steps and up-to-date safety practices, Indian producers can boost their reputation, keep customers safe, and earn the trust they need to succeed worldwide. Getting FSMA right today is the best way to build a safer, stronger, and bigger bottom line for tomorrow.

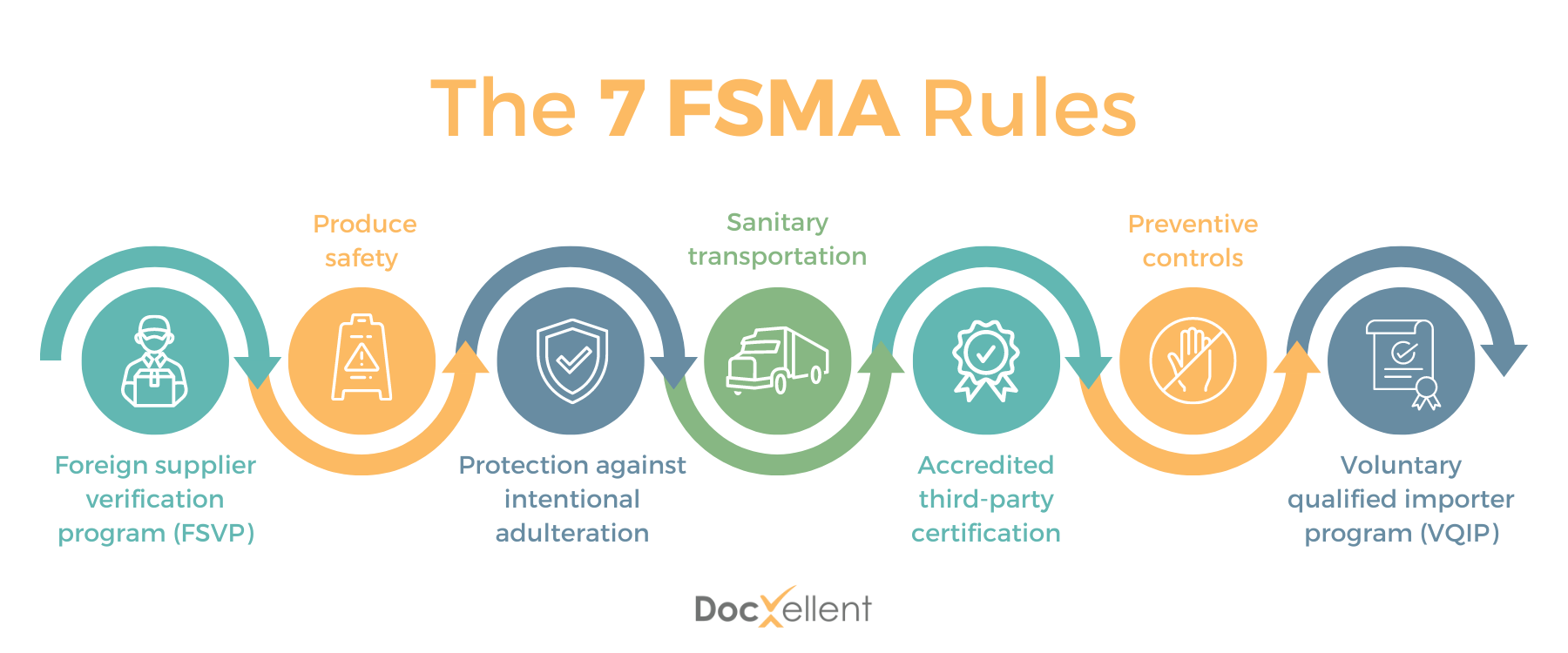

FSMA is the most significant rewrite of U.S. food safety rules in over 70 years. The new law instructs us to stop waiting for problems to explode; instead, we must plan and prevent them before they even reach our factories.

For Indian food makers, the Food Safety Modernization Act is a double-edged sword: it raises the bar but also opens doors. Companies that get the hang of FSMA now can stand shoulder to shoulder with big players in the rewarding U.S. market. Ignore the rules, though, and the price is steep—shipment refusals and even import bans knock at the door.

The FSMA doesn't just target big American firms; it hits any place that makes, processes, packages, or stores food for people or pets. So, everything from your small turmeric operation to the latest freeze-dried meal plant is in the crosshairs if the U.S. is the target market.

FSMA preventive controls go way beyond the "let's check for a minute at the end" approach. You're required to map out every hazard—biological, chemical, or physical— and manage it with techniques baked right into the process. No more "we'll fix it later" mentality; every action has to be documented and proven effective.

A strong food safety management system is the cornerstone of FSMA compliance. You will develop thorough safety plans, conduct a hazard analysis, outline preventive measures with detailed checklists, establish monitoring procedures, create backup plans in case of an issue, and ensure everything is double-checked. Logging is now required; it is no longer optional.

Somebody has to be the GPS for the whole food safety journey. Indian firms must put qualified employees in the captain's chair. They need the proper training to design and roll out preventive controls. The Food Safety Preventive Controls Alliance offers training packages that meet the "FDA says yes" criteria.

The food preventive controls differ from the usual quality checks. Standard quality tests often check the finished item, but preventive controls tackle hazards as they occur. So, spice makers should use established treatments to kill germs instead of relying on end-product tests to catch every problem. For facilities that make ready-to-eat foods, environmental monitoring can't be an afterthought. Your food safety system requires clear plans for testing surfaces and air for Listeria, as well as procedures for cleaning and addressing issues when this germ is detected. Stopping germs in the environment means they can't contaminate the food later.

The Food Safety Modernization Act suggests that food safety begins and ends in your plant. Indian manufacturers must also ensure that the ingredients they purchase are safe. That means you'll need to conduct audits of your suppliers, check certificates of analysis, and monitor their food safety records to ensure nothing slips through the cracks.

Keeping a handle on raw materials is a big deal under FSMA regulations. Nut importers dealing with spices have to watch out for aflatoxins in shipped nuts, certain ingredients that might carry heavy metals, and any bugs in the raw ag materials. To deal with these threats, each processor must have clear documentation on the prevention steps they use.

For traders in the States, Foreign Supplier Verification Programs add a few extra hoops to jump through when bringing in ingredients. Indian suppliers can support their customers by obtaining FSMA FSVP certificates. Demonstrating that their plants already adhere to FSMA food-safety practices reassures buyers that these manufacturers take U.S. regulations seriously.

The Food Safety Modernization Act requires anyone in charge of preventive controls to undergo specific training. SGS offers hands-on courses on hygiene and preventive controls, helping Indian food businesses teach their staff in-house, thereby retaining expertise.

Excellent training must cover hazard analysis, design of preventive controls, monitoring methods, problem resolution, and subsequent verification steps. It's also smart to hold regular refreshers, so that your team hears the latest updates on FSMA rules and the newest industry best practices.

Keep careful records of everything your team trains on. Training certificates, attendance sheets, and tests showing what staff can do all go into your compliance file. For food safety tasks, this documentation demonstrates that you are maintaining seasoned personnel on the team.

Your competitors have already made significant investments in food safety systems, giving them an advantage in the FSMA compliance box. Get your share of the market by tightening your FSMA plan now! Don't be caught off guard by FSMA regulations and allow your competitors to take market share in the US with food safety systems.

Are you prepared to use FSMA headaches as a covert weapon? For Indian food producers interested in the U.S. market, SGS offers FSMA solutions specifically designed for them. Our pros kick things off with gap checks, then build your food safety management system, run training, and stick around to make sure you meet every FDA box.

We also make sure you meet GFSI and other top standards, so you step onto the U.S. stage with the credibility you need. Ping SGS now to book your FSMA check-up and see how our proven experts can speed up your U.S. exports while keeping you in the clear with the rules. Your U.S. market sprint begins with our know-how—let's get rolling today.